DENMAG V-TYPE CRANE TRIUMPHS WITH THE RED DOT AWARD

- Award at one of the most important competitions for product design

- International jury honours the unique crane girder design

- Second design prize in a short time

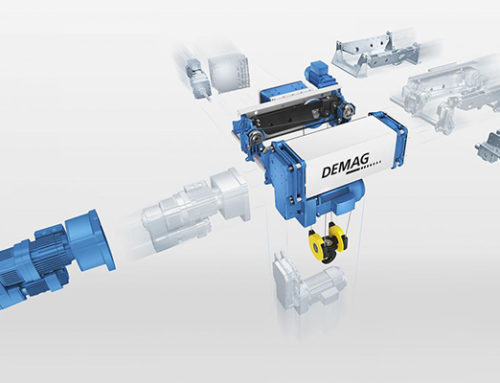

The Demag V-type crane has won one of the most important and prestigious competitions for product design worldwide, the Red Dot Award: Product Design 2015. The international jury made up of designers, design professors and trade journalists from 25 nations awarded the innovative crane girder design the Red Dot for high design quality in the machinery product category. The Demag V-type crane is characterised by its V-shaped structure comprising vertical struts and tapered diaphragm joints. True to bionics, the developers based their design on the honeycomb-like structure of bones. This deliberately uses material only where it is needed.

In total, around 5,000 products from 56 countries were submitted for the Red Dot Award: Product Design, in this its 60th year. As the winning product, the Demag V-type crane will be shown from 29 June to 26 July 2015 in a special exhibition in the Red Dot Design Museum in Essen, Germany, and will be part of the museum’s permanent exhibition in the following months.

This award is already the second design prize this year for the crane with patent pending. It won the respected iF Design Award at the beginning of February. “We are proud that the Demag V-type crane has now impressed the second high-class design jury”, says Andreas Hambrock, Head of the Universal Cranes business line of Terex Material Handling. “With its dynamic and translucent V-profile, our unique crane girder fulfils all the requirements of high-class design.”

The V-type crane also offers significant technical advantages compared to conventional cranes with closed box-section girders or I-beam girders. Its innovative architecture reduces the vibration frequency by 30 per cent, lowers the weight by an average of 17 per cent and doubles the lifetime to over 500,000 load changes.

The new girder concept therefore offers considerably greater efficiency in load transport and higher handling rates.

Leave A Comment